Cogeneration - Electricity and Heating from Wood

Wood is too valuable to be burned !

Allow me to introduce the technology of gasification , which is less used, but more efficient than the known classical technologies.

Classical technology for obtaining heat and power from wood is based on burning wood for heat and driving a turbine that produces electricity.

Combined principle of gasification for the production of heat and electricity used in a cogeneration plant (wood-cogeneration plant) uses wood optimally and conserves natural resources!

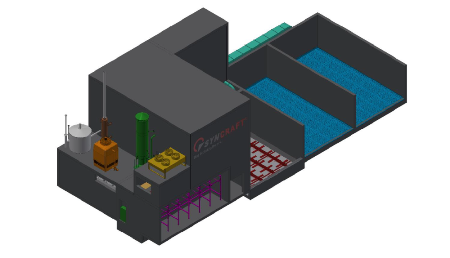

The heart of a cogeneration plant is efficient, robust thermal and electrical system that uses wood chips for gas production (wood-gas) in the reformer.

Wood gas is used in a gas engine, which on its axis has an asynchronous generator.

The efficiency of the system is seen in the consumption of 0,67 Kg wood residues per hour to produce 1kW of electricity.

We Should take into account that the production of gas is almost independent of the quality of wood (bark, branches, ... are used for wood chips), which significantly reduces costs in the production of heat and electric energy.

Wood residues as raw material for heating is 30% cheaper than gas, 50% of the electricity or fuel oil, while electricity produced is sold and pays investment!

The system maintenance is simple and can be done without the need for expert, but it should provide 20 minutes a day for basic maintenance.

Using wood-gas to produce electricity and heat, you can be independent of electrical distribution and purchase of gas.